Are you tired of seeing your alloy wheels scuffed, scratched, or damaged? Don’t worry, there’s a solution! Introducing the Alloy Wheel Repair Machine, a revolutionary tool designed to bring your wheels back to life. Whether you have a wheel repair shop or simply want to restore your own wheels, this innovative machine is a game-changer.

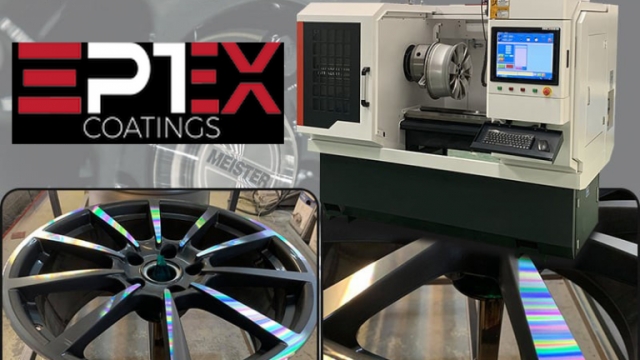

One of the key features of the Alloy Wheel Repair Machine is its wheel repair lathe, which allows for precise and efficient repairs. With this lathe, you can easily remove imperfections, such as dents and scratches, without compromising the integrity of the wheel. The vertical wheel repair lathe provides a stable platform for the wheel, ensuring accurate and consistent repairs every time.

When it comes to finding the right alloy wheel repair machine, look no further than wheelcncmachine.com. This website is the official online platform of Taian Haishu Machinery Co., Ltd., a reputable company specializing in CNC wheel machinery. With their expertise and commitment to quality, you can trust that their Alloy Wheel Repair Machine will exceed your expectations.

Don’t let damaged alloy wheels ruin the appearance of your vehicle. Invest in an Alloy Wheel Repair Machine and bring back the shine and elegance to your wheels. With its advanced features and the expertise of wheelcncmachine.com, you can confidently revive your wheels and turn heads wherever you go.

Different Types of Wheel Repair Machines

In the world of alloy wheel repair, there are several different types of machines available to help bring your wheels back to prime condition. Each type of machine has its own unique features and capabilities. Let’s take a closer look at some of the most commonly used wheel repair machines.

Wheel Repair Lathe: A wheel repair lathe is a versatile machine that is designed to restore damaged alloy wheels. It utilizes precision cutting tools to remove kerb marks, scratches, and other imperfections from the surface of the wheel. This type of machine is known for its accuracy and effectiveness in restoring the wheel’s original finish. By carefully shaving off the damaged areas, the wheel repair lathe allows for a seamless repair, leaving the wheel looking as good as new.

Vertical Wheel Repair Lathe: Similar to the wheel repair lathe, the vertical wheel repair lathe is specifically designed for larger, heavy-duty wheels. This type of machine is often used for repairing commercial truck wheels or heavy machinery wheels. With its vertical design, it provides enhanced stability and control when working with larger wheels, ensuring a precise and efficient repair process.

Alloy Wheel Repair Machine: An alloy wheel repair machine is a comprehensive solution that combines various repair techniques into a single, compact unit. This type of machine typically includes features such as wheel straightening, polishing, and powder coating functions. It offers a one-stop solution for repairing a wide range of wheel damages, allowing for a quick and efficient repair process. By integrating multiple repair functions, the alloy wheel repair machine simplifies the overall repair process and reduces the need for multiple machines or tools.

When it comes to selecting the right wheel repair machine for your specific needs, it’s important to consider factors such as the size and type of wheels you’ll be working with, as well as the complexity of the repairs required. By choosing the right machine, you can effectively revive your wheels and restore their original beauty.

Advantages of Using Alloy Wheel Repair Machines

Alloy Wheel Repair Machines offer several advantages when it comes to repairing and refinishing wheels. These advanced machines have revolutionized the wheel repair industry, providing efficient and high-quality solutions for various wheel damages. Here are three key advantages of using Alloy Wheel Repair Machines:

Enhanced Precision and Accuracy:

Alloy Wheel Repair Machines, such as the wheel repair lathe and vertical wheel repair lathe, are designed with precision in mind. These machines utilize advanced technologies to ensure accurate and precise repairs, allowing wheel technicians to achieve seamless results. With their ability to restore the original shape and balance of damaged wheels, these machines offer exceptional precision that is difficult to achieve through manual repairs.Time and Cost Efficiency:

With Alloy Wheel Repair Machines, wheel repair and refinishing processes are significantly streamlined, leading to improved time and cost efficiency. The automated functionalities of these machines enable technicians to complete repairs in a faster timeframe, reducing the overall labor required. Moreover, by eliminating the need for costly wheel replacements, Alloy Wheel Repair Machines can help vehicle owners save money by presenting a more cost-effective solution.

Cnc Alloy Wheel Turning MachineVersatile Repair Capabilities:

Alloy Wheel Repair Machines are designed to address a wide range of wheel damages, making them highly versatile in resolving various issues. From repairing curb rash and scratches to fixing dents and bends, these machines can handle different types of wheel repairs. Additionally, they can be used with different wheel sizes and materials, ensuring compatibility with a diverse range of vehicles and wheel types. This versatility makes Alloy Wheel Repair Machines a valuable asset for both automotive repair shops and individual car owners.

By leveraging the advantages offered by Alloy Wheel Repair Machines, technicians can effectively revive damaged wheels and restore them to their former glory. These machines not only deliver precise repairs but also enhance efficiency and provide a cost-effective solution, showcasing their importance in the wheel repair industry.

Please let me know if there is anything more I can assist you with.

Choosing the Right Alloy Wheel Repair Machine

When it comes to selecting the perfect alloy wheel repair machine, there are a few key considerations to keep in mind. First and foremost, you need to think about the specific features and capabilities that you require. Is versatility important to you? Are you looking for a machine that can handle both vertical and horizontal repairs?

Another crucial factor to consider is the reputation of the manufacturer. You want to ensure that you are investing in a high-quality machine from a reliable and trustworthy source. Taian Haishu Machinery Co., Ltd., the manufacturer behind wheelcncmachine.com, is a professional designer and supplier of CNC wheel machinery. With their expertise in the industry, you can be confident in the quality of their alloy wheel repair machines.

Lastly, budgetary considerations play a significant role in the decision-making process. It’s important to set a realistic budget and find a machine that offers the best value for your money. Keep in mind that investing in a durable and efficient machine may require a slightly higher upfront cost, but it can ultimately save you money in the long run.

By carefully considering your specific requirements, the manufacturer’s reputation, and your budget, you can make an informed decision and choose the right alloy wheel repair machine for your needs. Remember, a well-selected machine can help you revive your wheels and keep them in top condition for years to come.