In a world where efficiency is paramount, supply chain optimization emerges as a critical focus for businesses across various industries. It refers to the strategies and practices employed to enhance the flow of goods and services from suppliers to customers. By streamlining processes, reducing costs, and improving service levels, organizations can deliver value more effectively, ultimately leading to increased customer satisfaction and profitability.

Understanding supply chain optimization

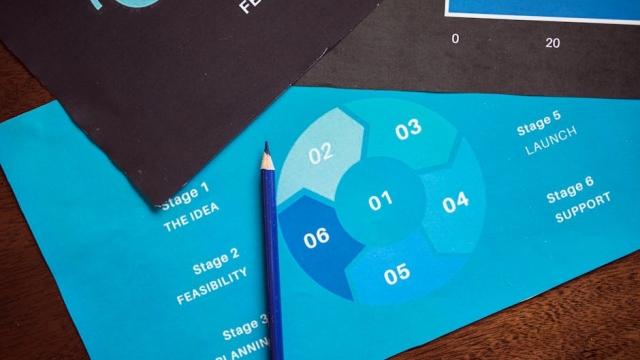

At its core, supply chain optimization involves analyzing and improving the entire supply chain process. This includes procurement, production, distribution, and logistics. By identifying bottlenecks and inefficiencies, companies can implement targeted strategies to enhance performance. The importance of this optimization cannot be overstated, as it directly impacts inventory management, order fulfillment, and overall operational effectiveness.

Best Practices for Ice Making Solutions

Particularly in industries reliant on ice making solutions, such as food and beverage, proper supply chain management is crucial. Here are some effective strategies to optimize these processes:

- Process Improvements: Streamlining ice production by regularly maintaining equipment and optimizing production schedules can lead to increased output and reduced waste.

- Inventory Management: Implementing a just-in-time inventory system can help manage stock levels efficiently, ensuring that ice is produced and delivered as needed without excess.

- Collaboration with Suppliers: Building strong relationships with suppliers can improve communication and lead to better forecasting and planning, ensuring timely delivery of raw materials.

Effective Cold Chain Management Strategies

Cold chain management poses unique challenges, especially when dealing with perishable goods. Maintaining product integrity throughout the supply chain is essential. Here are some strategies to enhance cold chain practices:

- Temperature Monitoring: Utilizing advanced monitoring systems to track temperature throughout the supply chain ensures that products remain within safe limits during storage and transit.

- Training and Compliance: Regular training for staff on best practices in cold chain management can significantly reduce errors and ensure compliance with safety regulations.

- Efficient Transport Solutions: Choosing the right transportation methods, such as refrigerated trucks or air freight, can optimize delivery times while maintaining product quality.

| Strategy | Benefit |

|---|---|

| Process Improvements | Increased output and reduced waste |

| Just-in-Time Inventory | Efficient stock management |

| Temperature Monitoring | Maintained product integrity |

Conclusion and Actionable Tips

In conclusion, effective supply chain optimization is pivotal for organizations aiming to enhance their operational efficiencies. By focusing on best practices in ice making solutions and implementing robust cold chain management strategies, businesses can navigate challenges while improving service delivery. Here are some actionable tips to consider:

- Regularly assess and refine processes to identify areas for improvement.

- Invest in training staff to ensure adherence to best practices in supply chain management.

- Leverage technology to monitor and manage inventory and temperature controls effectively.

By adopting these strategies, organizations can achieve a more streamlined and efficient supply chain, ultimately leading to improved customer satisfaction and business success. For more insights and solutions related to supply chain optimization, consider exploring additional resources at this site.