In the fast-paced world of warehousing and logistics, maximizing efficiency can make all the difference in a business’s bottom line. One of the often-overlooked tools for enhancing operational capacity is the forklift extension. These handy attachments transform standard forklifts into versatile machines capable of handling larger loads and accessing tight spaces. Whether you are moving oversized pallets or stacking materials high into a racking system, fork lift extensions can dramatically improve your productivity.

Understanding the benefits and uses of fork lift extensions is essential for anyone involved in material handling. By extending the reach of your forklift, you not only increase your lifting capabilities but also optimize space utilization in your facility. This guide aims to provide you with all the information you need to effectively use fork lift extensions, ensuring that you can maximize your reach and streamline your operations.

Understanding Forklift Extensions

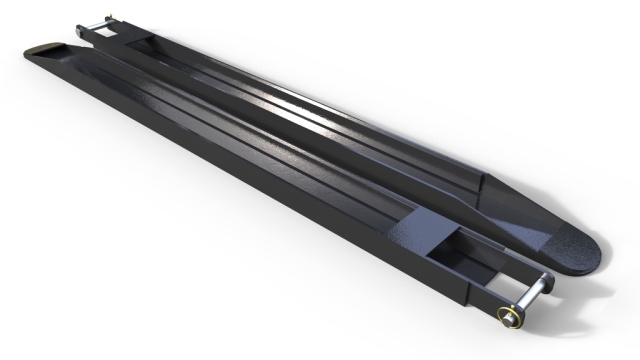

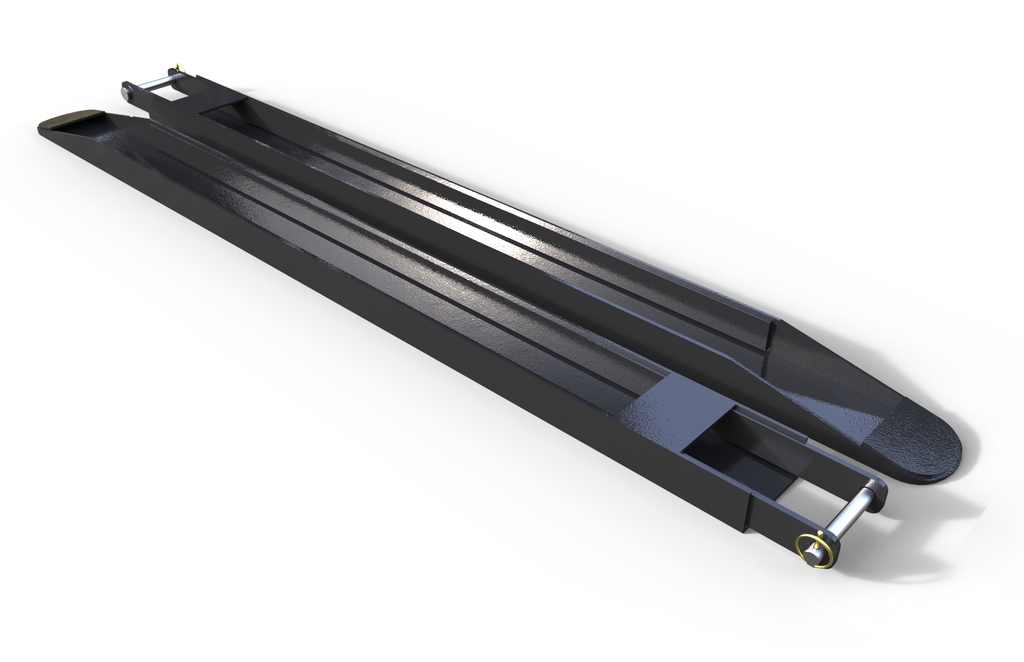

Forklift extensions are additional attachments that can be fitted onto the forks of a forklift to increase its reach and load handling capabilities. These extensions are particularly useful in various industries, such as construction, warehousing, and logistics, where moving heavy or oversized materials is often necessary. They come in various lengths and capacities, allowing operators to customize their forklifts based on specific tasks and requirements.

One of the primary benefits of using forklift extensions is the enhanced versatility they provide. By extending the reach of the forklift, operators can easily lift and transport items that would otherwise be difficult to handle. This can save time and reduce the physical strain on workers, leading to increased productivity and efficiency in operations. Moreover, with the proper extensions, forklifts can safely lift loads that are significantly longer than the standard forks can accommodate.

It is essential for operators to understand the limitations and safety considerations when using forklift extensions. Overloading the forklift or using extensions that are not compatible with the equipment can lead to accidents and equipment damage. Therefore, adhering to manufacturer specifications and guidelines is crucial. Proper training and operational procedures should be established to ensure that the use of forklift extensions enhances safety and effectiveness in material handling tasks.

Types of Forklift Extensions

Forklift extensions come in various types, each designed to enhance the capabilities of standard forklift tines. One common type is the slip-on extension, which simply attaches to the existing forks of the forklift. This type is ideal for temporary situations where extra reach is needed, such as lifting longer items like lumber or pipes. Slip-on extensions are easy to install and remove, making them a versatile choice for warehouses and construction sites.

Another type is the fork-mounted extension, which is permanently attached to the forklift forks. These extensions typically offer more stability and can handle heavier loads than slip-on extensions. They are often used in settings where heavy lifting of bulk materials is a regular requirement, such as in manufacturing or distribution centers. The fork-mounted extensions provide a secure solution for managing increased loads without compromising safety.

Lastly, adjustable extensions offer flexibility, as they can be resized to accommodate different load lengths. These extensions can be particularly beneficial when working with various sizes of cargo, making them suitable for industries with diverse lifting needs. Adjustable options allow operators to efficiently switch between tasks without the need to change equipment, maximizing productivity in busy environments.

Benefits of Using Forklift Extensions

Using forklift extensions can significantly enhance the versatility of your material handling operations. One of the primary advantages is the increased reach they provide. With extensions, forklift operators can lift and transport longer loads that would otherwise be difficult to handle. This is particularly beneficial in warehouse settings where space is limited but long materials need to be stored or transported, allowing for efficient use of equipment and labor.

Another major benefit is the improved safety that comes with using forklift extensions. When handling oversized or cumbersome items, extensions help distribute the weight more evenly, reducing the risk of tipping and accidents. This can lead to a safer work environment, minimizing the chances of injuries and damage to goods. Operators are more confident when using the right attachments, as they can maneuver loads with better control.

Lastly, forklift extensions can lead to increased productivity. By enabling the handling of larger loads without the need for additional equipment, businesses can optimize their workflows. Time spent reloading or switching between different machines can be drastically reduced, allowing for smoother operations and faster turnaround times. This efficiency not only saves on labor costs but also boosts overall operational effectiveness.

Safety Considerations for Forklift Extensions

Forklift Parts

When using forklift extensions, safety should always be the top priority. It is essential to ensure that the extensions are compatible with the forklift being used. This includes checking the manufacturer’s guidelines for load capacities and appropriate use. Incompatible extensions can lead to instability when lifting loads, increasing the risk of accidents. Operators must also receive training on how to properly attach and detach extensions to prevent mishaps during operation.

Another crucial consideration is the weight distribution of the load. Forklift extensions can alter the center of gravity, making it more challenging to maintain balance. Operators should always be cautious about the combined weight of the load and the extension. Overloading the forklift, even with extensions, can lead to tipping or loss of control, which can endanger both the operator and nearby personnel. Regular inspections of the extensions are also vital to ensure they are free from damage and functioning correctly.

Additionally, wearing appropriate personal protective equipment is necessary when operating forklifts with extensions. This includes hard hats, safety shoes, and visibility vests to enhance safety on the worksite. Establishing clear communication signals among team members can help ensure everyone is aware of the operations taking place, reducing the likelihood of accidents. By following these safety considerations, operators can effectively utilize forklift extensions while minimizing risks.